¶ Introduction

Classic Supply Cloud is the replacement for the current basic supply solution based on TecForm, reaching end of lifecycle and not mapped to TXML5.0

Buyer sends an inquiry or express order to the Order Core platform

Instead of routing messages to the Supplier's ERP system, the platform gets data from the TecCom Business Cloud in order to create an Inquiry/Order. Response with availabilities, prices, alternatives

¶ New import specification

Import specification describes which files and data can be imported for the upload process.

¶ Mandatory and relevant files for the process

| Filename | Mandatory? | Usage |

|---|---|---|

| article.csv | Mandatory | Match article number, brand, ean, TecDoc number and other identifiers |

| assortment.csv | Mandatory | Assortment groups make articles visible to buyers. Without an assortment, an article will not be visible to any buyer at all. |

| article_data.csv | Mandatory | Basic article information including min/max order quantity. Prerequisite for adding sales UoM, article description, alternative, discount group, packaging and external document information. |

| sales_uom.csv | Mandatory | Used to return valid price or availability information. |

| buyer_grouping.csv | Optional | Assign assortment-, article-, condition- and availability group to buyers. In case no direct group assignment for a buyer exists, the buyer will be assumed to be in the 'public' group. |

| availability.csv | Optional | Used to return availablities for requests and orders. Mandatory to perform valid orders for Classic Supply Cloud |

| article_description.csv | Optional | Article descriptions will be returned for requests and orders. |

| article_buyer.csv | Optional | Additonal information will be returned for requests and orders. |

| alternative.csv | Optional | Additonal information will be returned for requests and orders. |

| condition_group.csv | Optional | Mandatory to return price/allowance and charge information for requests and orders. |

| price.csv | Optional | Relevant to return price information for requests and orders. Hint: Remarks will be cuttedd to 35 characters for the response of requests and orders. |

| alc.csv | Optional | Relevant to return allowance and charge information for requests and orders. Hint: Remarks will be cuttedd to 35 characters for the response of requests and orders. |

| alc_head.csv | Optional | Relevant to return allowance and charge information on order level for requests and orders. Hint: Remarks will be cuttedd to 35 characters for the response of requests and orders. |

| packaging.csv | Optional | Additonal information for meassurements will be returned for requests and orders. |

| external_document.csv | Optional | Additonal information will be returned for requests and orders. |

All other files defined in Import Specificaton are not relevant and not used for Classic Supply Cloud.

¶ Example Files

Download the zipped example files to have a better understanding of the described file types.

¶ Getting connected with Connect 5

You have the possibility to use the old Basic Supply import files with limited functionality or use our new import format with full functionality.

Description for the integration settings can be found in Connect 5 chapter 3.4 TBC integration.

¶ Basic Supply

The old Basic Supply import files (Basic supply description) will be transformed in our new format.

The new Classic Supply Cloud needs an existing business relation. The provided partner numbers has to match to an existing business relation, otherwise the data can't be transformed respectively no request or order can be made.

Missing required information will be added as following

- Article

- Base UoM = PCE

- Current status = Normal

- Availabilities

- Dispatch Mode = Undefined

- Sales UoM

- Base UoM per UoM = 1

- Prices

- Prices will be imported as gross price

Additional restrictions

- Currency: the first currency in MatPrice will be used, prices with other currencies will not imported

- Rows with invalid types, e.g. wrong UoM, will not imported. The full list of types can be found here.

- Headers are not allowed in Basic Supply csv files.

¶ Establishing a connection without Connect 5

If you don't want to use Connect 5, follow the instructions in Getting started -Supplier

If you are a Buyer and want to retrieve complete article information, please check the following documentation: Article Search Data

¶ Usage of min/max order quantity

If with article_data.csv a min or max order quantity is defined for an article, this values are used to return the quantity for requests and orders.

If the article is availabe and the min order quantity is higher then the requested quantity, the response will have a change to this minimum quantity.

Same for max quantity, if the request quantity is higher than the max quantity and the article is available, the response will have a change to this maximum quantity.

Example for min quantity:

Min quantiy: 2 PCE

Available quantity: >= 2 PCE

Request quantity: 1 PCE

=> response: 2 PCE

Example for max quantity:

Max quantiy: 10 PCE

Available quantity: >= 100 PCE

Request quantity: 100 PCE

=> response: 10 PCE

¶ Dynamic Stock Decrease

With the functionality of Dynamic Stock Decrease the availability in TecCom Business Cloud will be reduced with the confirmed quanity when a order is sent to Classic Supply Cloud.

¶ Activation

To use this service you have to activate this in TecCom Portal.

Login as an administrator in TecCom Portal and go to Administration - Business Cloud.

To set this up follow the steps on page Getting started - Supplier

¶ Stock Decrease Prerequisite

When a order is send to TecCom Business Cloud and the setting is enabled, this additional points must be fullfilled

- the confirmed quantity > 0

- the article can be uniquely identified by ean, product number, buyer product number or OE number, depending on the order information

- the buyer has a matching availability group, this can also be the group public

- the uom of the article in the order has the same uom from availabilty of the article

- the dispatch mode from the order is the same from availability or the dispatch mode is Undefind

If this prerequisites are fullfilled the availability quantity will be reduced with the confirmed quantity.

¶ Bahaviour for other Classic Supply Cloud settings

- Ignore special characters: if switched on, the material numbers sent in a message are normalized by removing any special characters before searching for the article in the database.

- Return requested material as-is: if switched on, the material numbers returned in the response will always be the same that were sent.

- Accept all line items (including errored and no available items): if switched on, all items that customer sends (orders and stock orders) will be written to the database and exported.

¶ BackOrder

If BackOrder is activated by supplier for a specific dispatch mode, the buyer can select in Trade Portal if he allows his Order to be taken into backlog.

¶ Supplier BackOrder Settings

Supplier has a possibility to specify if BackOrder is allowed per each specific dispatch type on his membership-profile page.

There are three options to be set:

- Only with BackOrder;

- Only without BackOrder;

- With or without BackOrder.

Based on the supplier settings, for each dispatch mode with IsActive = true listed in Memberprofile for Express Order Dispatch Modes and Stock Order Dispatch Modes, Classic Supply DispatchMode settings has this values:

- DispatchMode mapped from MemberProfile

- Backlog = OnlyWithBackorder (DispatchMode.BackOrderSettings = 1), OnlyWithoutBackorder (DispatchMode.BackOrderSettings = 0), WithOrWithoutBackorder (DispatchMode.BackOrderSettings = 2)

- Complete Delivery from dispatch mode

- Complete Shipment from dispatch mode

If no document could be found, for all tXML 5 dispatch modes the default settings are used: - Complete Shipment = true

- Complete Delivery = true

- Backlog = 'WithOrWithoutBackorder'.

¶ BackOrder logic

Supplier BackOrder settings are taking into consideration along with the buyer settings while performing TXML5.Order/Request in Shopping Cart.

For example:

- if Supplier has 'Only without BackOrder' set for some specific dispatch type, then on GUI in TXML Shopping Cart the buyer can set only the same settings for transaction with the supplier mentioned dispatch mode;

- if Supplier has 'With or without BackOrder' set for some specific dispatch type, then on GUI in TXML Shopping Cart the buyer can set any BackOrder settings for transaction with this supplier and selected dispatch mode.

If activated, articles can be put on backorder and send later for this delivery method.

If BackOrder settings are activated and if the supplier has imported article_data.csv with max_order_qty and min_max_order_uom filled in, then at the Order/Request process max_order_qty is considered during availability calculation.

MaxOrderQty for each specific article of the Supplier is determined in the same way as regular availability (article_id match, buyer_grouping match, quantity can be expressed in UoM properly).

In the checkout ordering process, the difference between available quantity and max order quantity is taken into backorder and the quantity confirmed

If the supplier hadn’t fill out the max order quantity, no amount is taken into backorder for this order line (to avoid a bad user experience, like a buyer ordering 1 million items and the supplier confirming always everything in every order).

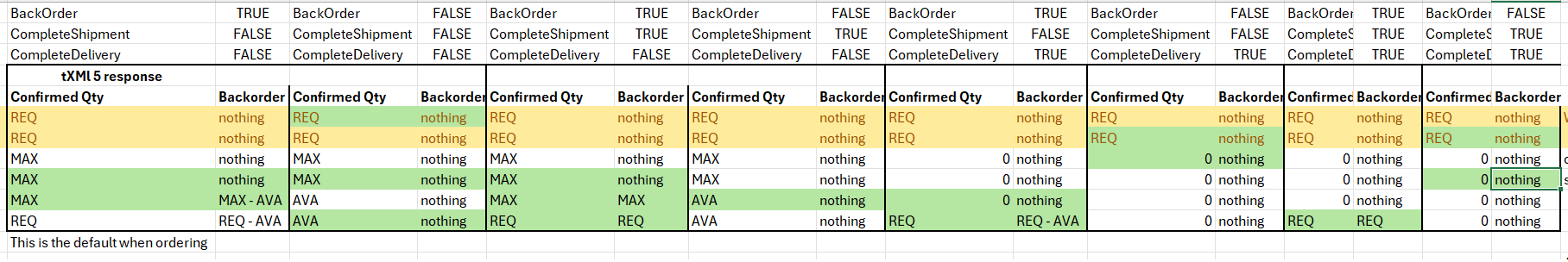

All possible flows for calculation considering settings combinations for BackOrder feature are represented on the table below:

Example:

GIVEN:

BackOrder=true

StockDecrease=true

Availability = 10

MaxQty =5

Requested Qty = 6

RESULT after Order execution:

Confirmed Qty = 5;

BackOrder = 1;

Decreased Availability in database = 5 (if Dynamic Stock Decrease option is enabled; if disabled - no changes in database for availability amount).

The buyer can see all relevant information after Order/Request performed in the Shopping Cart.

Also the buyer can visit the TecCom Portal Transaction Monitoring UI to check the confirmed quantity and the Backorder quantity for each order line.